Quality wall protection with our SecoFLEX and SecoTHERM masonry paint coating. A reliable wall protection solution.

EcoSpray-Foam Systems uses SecoFLEX for masonry protective coating, this high quality product is one of the best on the market and can provide an optimal solution for many property defects. One example where masonry protective coating can be sufficiently applied is on costal houses and properties where the salt (chloride) can have drastic effects on the structures of a property, causing decay, rotting and a shortened lifespan. This product is manufactured by one of the largest paint companies, worldwide. Additionally, the SecoFLEX masonry paint is around 6 times stronger than that of standard masonry paint.

Product ensures 100% waterproof, protecting your walls and prolonging structural lifespans.

Up to 400% elasticity for permanent bridging of cracks and fissures.

Microporous - constantly breathing allowing for release of moisture.

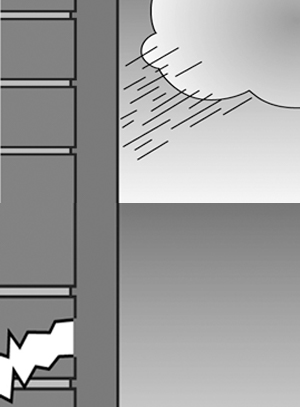

Facades are subject to harm from soot, sand and dust, especially in more densely populated areas. Additionally acid rain has effects on facades along with sulfur dioxide and other airborne substances, all penetrating masonry pores.

Algae is disseminated via wind and becomes fixated onto facades. Environmental factors such as temperature, carbon dioxide, moisture and light all contribute to the spread of algae. In harsher conditions, facades are prone to greater damage and turn green, brown or red.

With sufficient damp-proofing on facades, such as SecoFLEX masonry paint, salts can damage exterior walls, causing them to flake and crumble. The spread of salt on to facades dries out, concentrates and forces the plaster to flake.

Cracking can lead to water penetrations, frost damage and mould growth if facades are not treated correctly. Cracking can be in the form of hair cracks or web-like cracks and can be caused by heavy paint along with harsh weather conditions that penetrate the facade.

This is a sign of poor adhesion, if coatings are applied to insufficiently firm substrates, the internal stresses in paint lead to the formation of cracks. Water is then able to ingress and create flaking of the facade. Avoid this with quality masonry paint wall coating.

Facades that are exposed to moisture absorption and temperature change may be on the receiving end of blistering. Cycles of warming and cooling expose facades to blistering, especially from weak areas of the substrate.

All surfaces will be thoroughly cleaned and if any algae and black mould exist on the wall, we need to have the spores treated prior to any new application.

We apply fungus killer to all the areas.

Power jet wash all surfaces using a pressure of not less than 3000psi. the objective being to remove all the lichen.

We repair any holes, cracks and damaged render with Pegacrete repair mortar.

We Fill up cracks < 0.5 cm with Murfiller (waterborne acrylic paste filler).

We ensure all bare, porous and chalking surfaces are primed and stabilised with Pegafix impregnating and fixating primer.

Application of the SecoFLEX waterproofing system.

We apply by airless spray 2 coats of secoFLEX of at least 400g/m2 per coat.

This is the equivalent to more than 6 coats of standard masonry paint!

EcoSpray-Foam Systems ensures an optimal application of the SecoFLEX masonry product, to allow for lifelong duration and sustainability of the sealant. In order for us to provide our highest quality service, before any masonry applications, we must carry out the work during the correct conditions. Conditions that must be met are: stable and dry weather on clean substrate, allow for a 24hour drying time (unless otherwise specified) and the substrate must have a minimum temperature of +5℃, preferably between 15℃ and 25℃ and a maximum of 55℃. To meet these standards and to ensure that the product reaches its maximum potential we carry out the above process.

Dover White

Oyster

Pale Primrose

Buttermilk

Lemon Straw

Almond

Candy Floss

Nectar

French Grey

Kashmir

Evergreen

Quarry Red

EcoSpray-Foam Systems uses SecoTHERM to not only waterproof the exterior walls of your home, but also, to enhance the thermal resistance of your walls and property. SecoTHERM is extremely resistant to both weathering and UV rays, repelling water, prevetning damp growth and improvign the overall thermal resistance of your exterior walls. .

Reduces water absorption

Lowers thermal conductivity by up to 75%

Certified with ISO 15148.

SecoTHERM has a 20 year guarantee.

SecoTHERM saves energy.

Less susceptible to unwated growths.

Typcially, water and UV degradation are fundamental factors that damage masonry surfaces on residential homes. However, SecoTHERM has been devleoped to the highest standards, combatting against this and more and is the ultimate weather protection standard for walls and bricks. SecoTHERM is unaffected by UV rays and creates a barrier against water ingress. By ensuring a dry masonry wall you can improve your homes thermal resistance, which is accomplished by SecoTHERM.

Dampness is one of the major causes of decreased thermal conductivity, wall degradation and more. Mositure builds up in your masonry bricks, creating wet cavities and weakened walls. Results from certain tests indicate that if your wall has a damp content of only 5%, your insulation performance can lower as much as 50%. This factor is even more so prevelant in cavity wall insulation, as the insulation becomes wet, the thermal value is weakened tremendously.

By treating your exterior walls with SecoTHERM, you can drastically reduce the water absorption. For example, on a porous brick, the water absorption will be reduced by up to 95%. SecoTHERM has been tested on concrete, mortar, sandstone and brick. Additionally, when you use SecoTHERM, your property will be protected for over 20 years. Additionally, SecoTHERM prevents the growth of mould and microorganisms, which can damage your exterior surfaces and make your property look stained.